Entema is a family company established in 1992 in order to provide qualified engineering services to the local industrial plants in Corlu which has been one of the leading textile headquaters in Turkey since. Soon after, the company has focused on producing textile finishing machinery and chose drying processes as its main field of work.

By the advantage of being specialized in a single subject, Entema has developed high capacity, efficient and energy saving machines which achieve high quality results of increased fabric properties as swelling, softening, minimum shrinkability. As a result the company achieved its well-deserved place in the field in short time. In the following years, as participating in many textile exhibitions abroad, Entema has internationaly exhibited its products which have improved more by progressing r&d activities and experience, and became a world-wide known brand. Currently, many Entema products are in service in many textile manufacturing countries in the Far-East, Asia Pasific, Central Asia, Middle East, North Africa and Latin America. The present repeated purchase orders from domestic and foreign manufacturers for their additional needs, show the success and achievement of Entema products. Besides its unique and internationaly patented designs which have been brought into the textile sector by the company's on-going r&d activities, many products with customer specific designs for special needs and conditions have been also being produced.

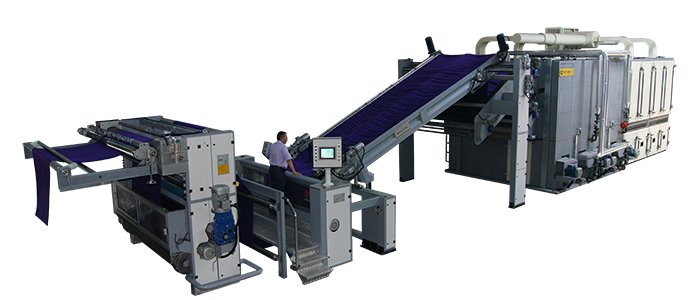

4 Pass Relax Dryer QUADRO:

Fabric pass: 4 pass

Number of chambers: 2 to 7 chambers

Conveyor belt width: 1600mm to 3350mm

Heating system alternatives: Natural Gas, LPG, Steam or Thermic Oil

Mechanical belt speed: Step less 0 to 60m/min

Maximum working temperature: 170 °C

Blowers: Special desing, high efficiency, diagonal location, two blowers on each chamber

Fabric feeding: Step less by multiple point

Conveyor belt direction control: Electro-pneumatic from both side

Option 1: Variable wave effects by special designed air jet tumbling system

Option 2: Exhaust air humidity controlling system

Option 3: Fabric humidity control system

Option 4: PLC controlling by full automation package

Equalizing Relax Dryer:

Leveled Input

Equalizing unit: Vertically inox chain, squeezing and – or chemical foulard, centering device with slatFabric pass: 1, 2, 3 or 4 pass

Number of chambers: 2 to 7 chambers

Conveyor belt width: 1600mm to 3350mm

Heating system alternatives: Natural Gas, LPG, Steam or Thermic Oil

Mechanical belt speed: Step less 0 to 60m/min

Maximum working temperature: 170 °C

Blowers: Special design, high efficiency, diagonal location, two blowers on each chamber

Fabric feeding: Step less by multiple point

Conveyor belt direction control: Electro-pneumatic from both side

Option 1: Variable wave effects by special designed air jet tumbling system

Option 2: Exhaust air humidity control system

Option 3: Fabric humidity controlling system